he cold chain logistics has expanded to an industry with large scale, professional equipment, various involvement of industries and numerous employees. However, there are problems that urgently need to be solved in its operation, managing performance and control.

On the other hand, the outdated monitoring techniques and lack of effective management on food and drug cold chain logistics are the biggest bottlenecks in our country. Other problems like non-unified data system, low instantaneity, regulatory disconnection, responsibility partition, alarming incapability and high loss rate.

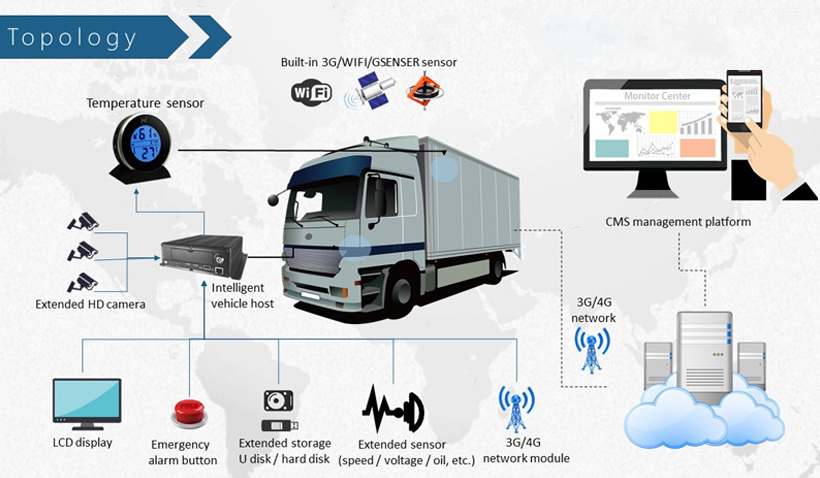

Surveillance Demand Analysis of Refrigeration Vehicles

A. Speeding Alarm: When exceeds the limitation, vehicle alarms and generate a report. It prevents the vehicle from over-speed accidents and loss to company.

B. Fuel Alarm: Instantaneous loss or low remnant of the fuel will trigger the alarm. It prevents the occurrence of oil theft, and provides effective data for companies to analyze the transportation cost.

C. Temperature Alarm: Container temperature RTA(Real Time Analyze)

D. Real time surveillance: monitors the driving status of the driver, cargo and road conditions through cameras and sound pick-ups.

E. Location surveillance: Vehicles on duty can be located by the monitoring center. Incorporating online maps, the location and trails of the car will be shown.

F. Dispatch: Vehicles on duty can receive task arrangement and adjustment from monitoring center.